Teksid block conversion for 03 / 04 Cobras.

If you’re rebuilding and considering going to the very strong aluminum Teksid block here’s some great pictures and comparisons I’ve taken when doing the conversion to help others. It also tracks and points out some key info you need to be aware of.

The front of the two blocks. The aluminum colored block, of course, in all the pics is the Teksid. The darker one is the factory cast iron Romeo block.

The teksid

The stock

The rear of the two blocks

Rear of teksid. Notice the shape of the rear plate that holds the rear main seal is different. Be sure and get the teksid plate with your block

Stock block

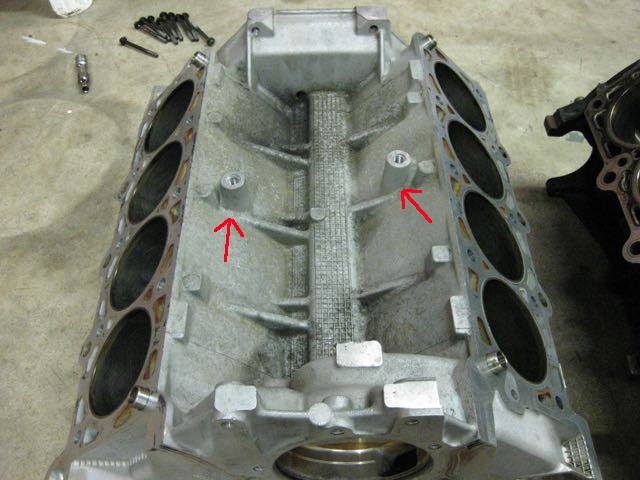

Teksid block has these two knock sensor bosses in the valley. The lower intake will not fit with them there. You need to grind them down.

Here they are ground down for clearance.

Stock block valley for reference

Nipple behind water pump on stock block has two o-rings and a slip fit.

Teksid has a barbed fitting which you can see I started smashing here. Had to apply heat and knock out. Mine was so seized up I had to have a machine shop turn out the remaining pieces and clean the hole up.

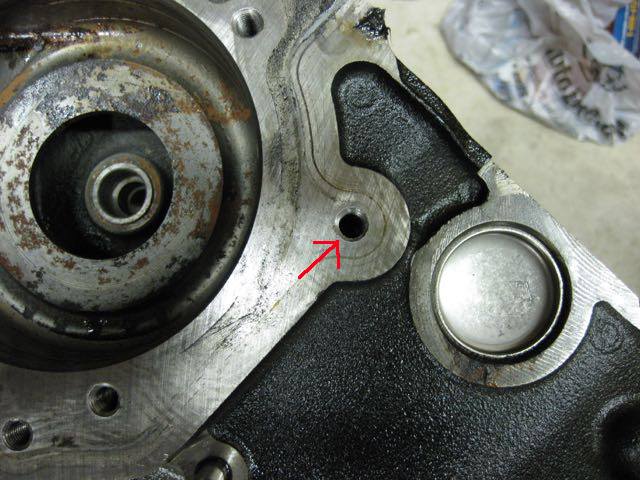

Stock block has this extra hole right by the driver’s side motor mount that does not exist on the teksid block. Generally not a big deal but at the time I had my J&S Vampire knock sensor attached here as have others. You need to move it else where when going Teksid.

Same view on the Teksid for reference.

Stock block has dowel pins pressed in block where chain tensioners pivot. They are thick and strong. The teksid has 6 mm threaded holes. You need to drill and tap them to 8 mm and use aftermarket dowels on the teksid.

Same view on Teksid. Notice threaded holes instead.

Stock block has 4 bolt mains.

Teksid has 6 bolt mains. If your motor is already studded with ARP hardware you’ll need new hardware.

Teksid mains on the left. Stock on right.

Also different side bolts into the mains. Stock on left and teksid on right.

Stock mains have the jack screws in the main caps.

Teksid mains just have threads in the main caps.

Jack screws are in the block on the teksid.

Back side of jack screws in teksid.

This timing bolt hole on the teksid block is in a different spot.

Same bolt hole on the stock block.

As a result this timing cover bolt will have no hole. It’s an easy fix. Just drill and tap it. You will have to shorten the bolt though. If you drill it full length it breaks into a water jacket and then you have to use pipe thread sealant on the bolt.

Here’s the new bolt hole drilled. You MUST plug the old hole with some silicon or you’ll have an oil leak as the timing cover seal goes directly over the old hole and oil will slowly weep out.

If you drill to far it’ll go through and you’ll have a hole like this. For reference the block is exactly 3/4” thick at that spot where you drill and tap. So I drill down 5/8” and shorten the bolt accordingly.

Passenger’s side Teksid for reference.

Passenger’s side stock block for reference.

Due to main cap differences the stock windage tray does not fit. However the full length 3 valve windage tray fits perfectly. You will need to remove the two factory fins on the oil pan though for clearance.

Here’s with the full length windage tray.

The fins in the stock oil pan that must be removed.

The fins cut off. I would not try and remove the spot welds. This has left holes in many pans then requiring some welding to fix.